Consulting

Our consulting assignments are usually important strategic projects that are commissioned directly by the Executive Board. The objective is to optimize processes, component and quality costs and performance.

You have a vision for your group or your medium-sized company for the future. We will work with you to develop the right strategy and the appropriate roadmap to turn your vision into reality.

Our focus

Equipment I Processes I Technologies and costs in press shop I Toolmaking I Maintenance (equipment and tools) I Production and manufacturing engineering I infrastructure

Analysis - evaluation

At the beginning of a project, we always start with a precise analysis and evaluation of the current situation. The decisive benefit for our customers is the high precision and quality of our analyses. Both are the result of our special methodology and structure in the analysis and evaluation of data and information. In this important phase, we are already clearly superior to other companies. On this basis, the necessary measures and the further direction of the project are defined with the client.

Implementation - in engineering and shopfloor

Once the necessary measures have been jointly defined, the implementation phase begins. In this phase, we implement the agreed measures and our BEST PRACTICE solutions in order to achieve the greatest possible benefit for the customer.

In the realization phase, we bring our management experience and assertiveness to bear to ensure that the project goals are achieved. Finally at this point it becomes clear, why afu-tech is in a class of its own and why we are leading in what we do.

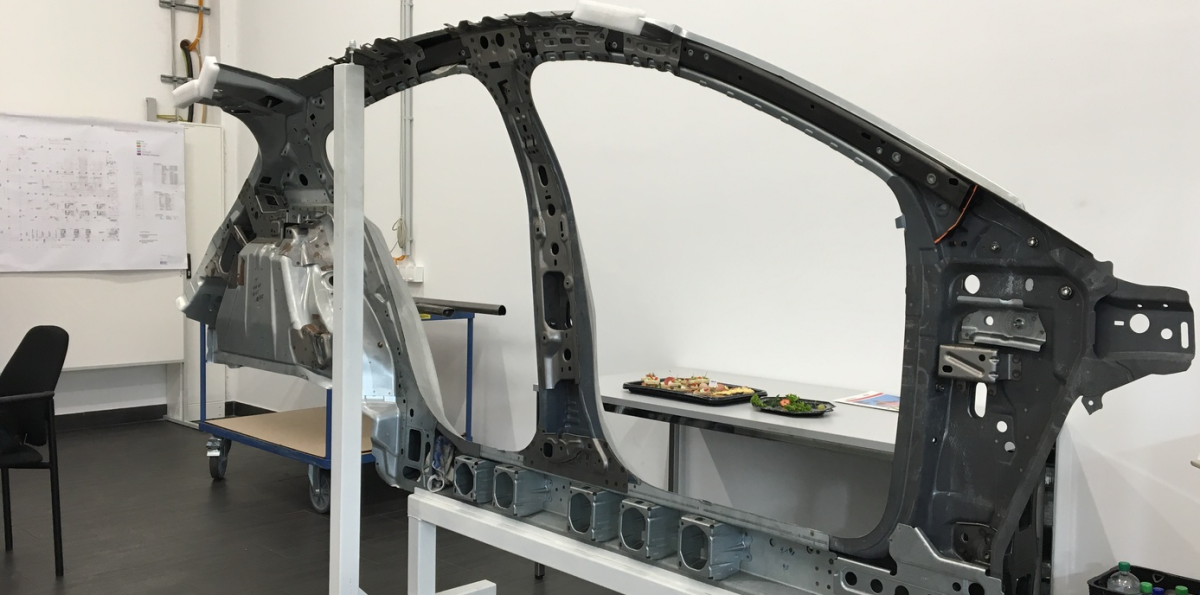

Feasibility studies for new vehicles - pressed parts - press tools

We define premises, strategies, processes and the equipment which is needed for the manufacturing of the pressed parts. This is the basis for our calculation of the prices of pressed parts, the body-in-white (aluminum, steel, AHSS and UHSS) and the associated equipment like tool sets etc., taking into account feasibility, plausibility and cost-effectiveness.

New-investments - retrofits - reorganizations - restructuring

We advise in the run-up to new investments in new production sites and the latest equipment and machine technology, but also on retrofits and expansions of existing production sites and complex infrastructure projects. We prepare feasibility studies and analyses, as well as due diligence reports for the BoD and investors.

The reorganization, restructuring or realignment of individual divisions or entire companies is in good hands with us.

Scope selection of consulting

- Analysis and optimization of costs and performance in the press shop, tool maintenance, toolmaking and operations

- Stamping studies on the feasibility, cost-effectiveness, plausibility and costs of pressed parts and pressing tools

- Optimization of component costs and quality, including stamping and forming tools and all necessary metrics

- Benchmarking

- Supplier management and building-lot supply

- Validation of processes and production equipment

- Make or buy process and decisions

- Logistics - internal and external warehouse management

- Integration of a high-bay warehouse into a production area

- Improve quality and costs of pressed parts

- Analysis and optimisation of casting-processes and castings incl. mega-casting